The world of manufacturing is changing fast, and the woodworking sector is no exception. From advanced robotics and smart sensors to cloud-based control systems, the rise of Industry 4.0 is ushering in a new era of efficiency and precision. For UK manufacturers, understanding these technologies isn’t just optional – it’s key to staying competitive in 2025 and beyond.

The digital shift in traditional manufacturing

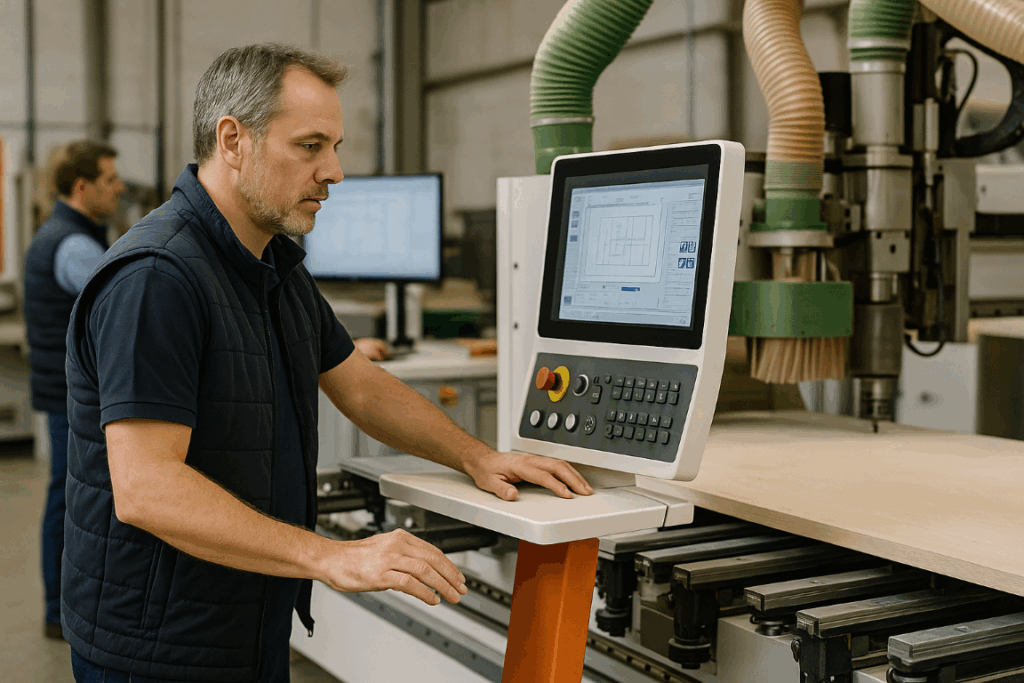

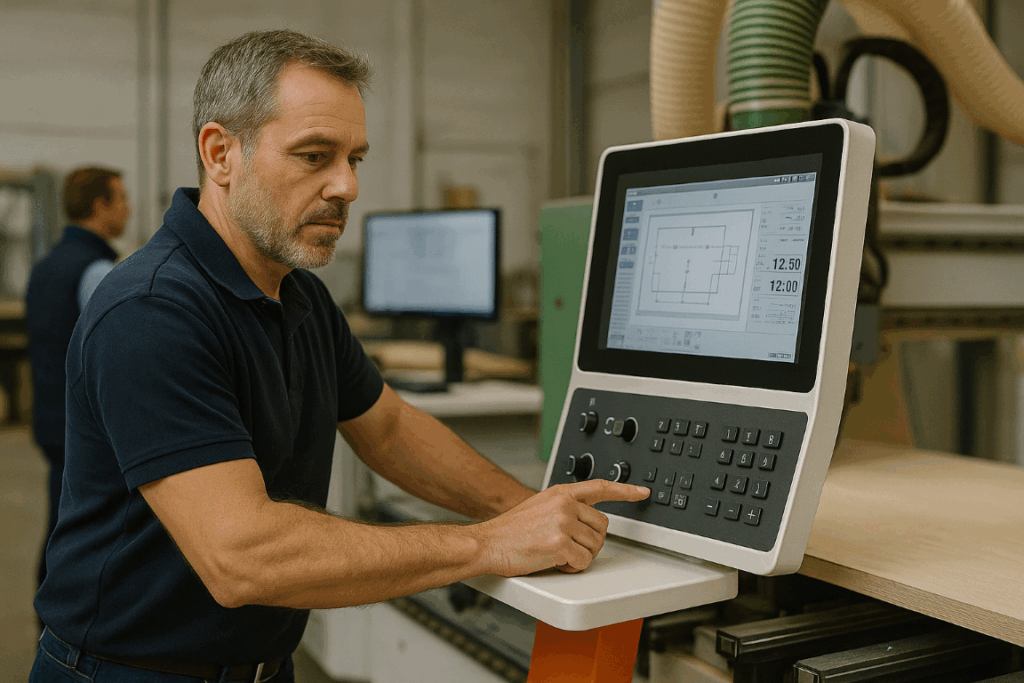

In the past, woodworking relied heavily on manual labour and standalone machinery. Today, many workshops are investing in connected systems that allow operators to track production in real time. Machines now communicate with each other through integrated networks, helping to predict maintenance issues before they occur and ensuring every process runs smoothly.

Automation, data analytics, and artificial intelligence are no longer futuristic concepts – they are practical tools improving productivity and product quality right now. Whether cutting panels, shaping frames, or producing bespoke joinery, digital control is redefining what precision really means.

Sustainability driving smarter production

As environmental concerns continue to influence the manufacturing landscape, businesses are looking for ways to reduce waste and energy use. Modern woodworking machinery is being designed to run more efficiently, often powered by electric motors that consume less energy than older hydraulic systems.

Even waste materials are being reused or repurposed – a trend particularly visible in the popularity of briquette machines that convert sawdust and offcuts into clean, burnable fuel. This approach not only lowers disposal costs but also supports carbon-reduction goals, aligning with the UK’s broader environmental strategy.

Modular design and flexibility

A key characteristic of Industry 4.0 is flexibility. Manufacturers are moving away from rigid, single-purpose setups in favour of modular systems that can adapt to new production needs. For woodworking, this means machines that can switch between profiles, joints, or materials without lengthy reconfiguration times.

This agility allows businesses to handle custom orders, small batches, and rapid design changes – all while maintaining efficiency. It also means that when technology advances, individual modules can be upgraded rather than replacing entire machines, keeping costs under control.

Data-driven precision and predictive maintenance

Modern woodworking machinery is increasingly fitted with sensors that monitor vibration, temperature, and cutting accuracy. These sensors feed real-time data into software platforms that detect early signs of wear or imbalance. Predictive maintenance not only avoids unplanned downtime but also extends the lifespan of expensive components.

Workshop managers can access this data remotely, enabling quick decisions and improved workflow planning. By combining data with smart algorithms, some systems can even optimise their own cutting patterns to reduce waste and shorten production times.

The rise of collaborative robotics

Collaborative robots – or cobots – are one of the most significant innovations in modern manufacturing. Unlike traditional industrial robots, cobots are designed to work safely alongside human operators. In woodworking, they can assist with repetitive or heavy tasks such as sanding, assembly, or material handling.

This collaboration allows skilled workers to focus on precision craftsmanship and complex design while the cobots handle the physical labour. The result is a safer, faster, and more consistent workflow that still maintains the human touch that defines quality woodworking.

Smarter workshops of the future

Imagine a workshop where every machine communicates seamlessly – from the panel saw and CNC router to the finishing line and extraction system. Orders move automatically from design software to production, with minimal manual input. This vision is quickly becoming reality thanks to integrated control systems and intelligent machinery.

These innovations are not limited to large factories. Even small and medium-sized woodworking businesses are adopting smart technologies to improve accuracy and reduce waste. As costs fall and training becomes more accessible, Industry 4.0 tools are now within reach of workshops across the UK.

A link between tradition and technology

While the latest digital innovations are changing the way materials are processed, the core principles of craftsmanship remain the same. Skilled joiners and furniture makers continue to rely on high-quality machinery to bring their ideas to life – only now, that machinery is faster, safer, and more sustainable.

Companies investing in advanced woodworking machinery are finding it easier to meet demand, maintain quality, and future-proof their operations against economic uncertainty. The ability to combine modern automation with traditional craftsmanship is what will define successful workshops in the years ahead.

Industry 4.0 FAQs

What is Industry 4.0 in manufacturing?

Industry 4.0 refers to the ongoing digital transformation of manufacturing, combining automation, AI, robotics, and data connectivity to make production more efficient and intelligent.

How does smart machinery benefit smaller workshops?

Connected systems allow small manufacturers to monitor performance, reduce downtime, and optimise output without needing a large technical team. Many solutions are now modular and scalable, making them ideal for growing businesses.

Are sustainable machines more expensive to run?

While initial costs can be slightly higher, energy-efficient machines often pay for themselves through lower running costs and reduced waste. They also help businesses meet environmental standards, which is becoming a major factor in securing new contracts.